NTT Adhesives

Home > Manufactured Products > Adhesives >NTT Adhesives

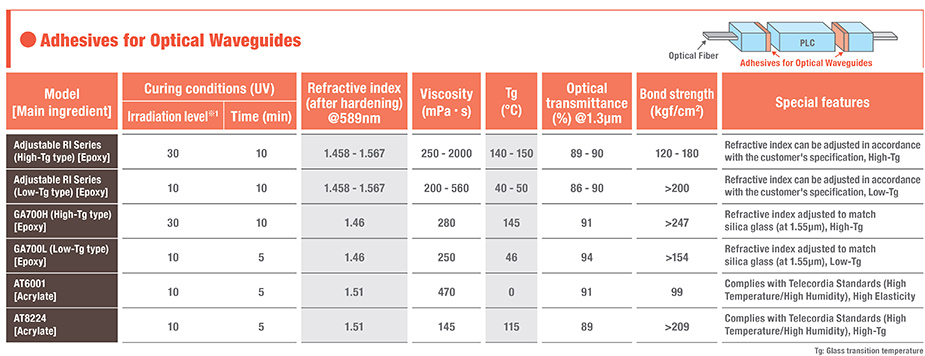

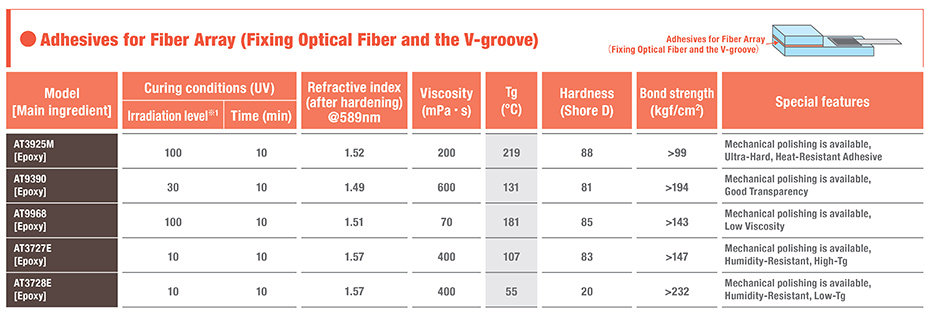

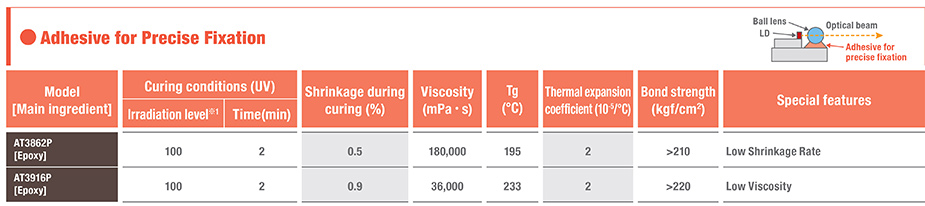

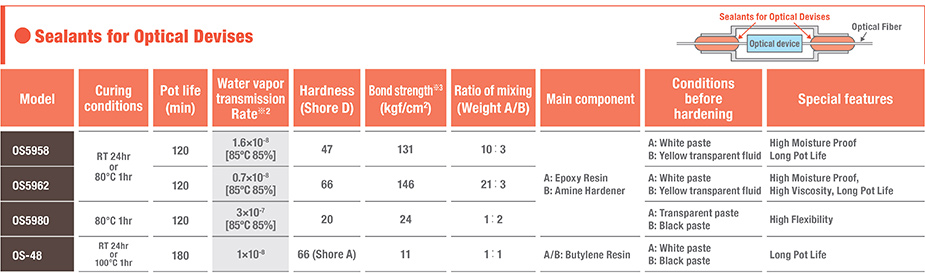

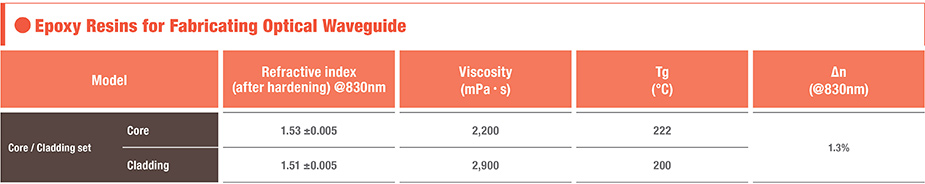

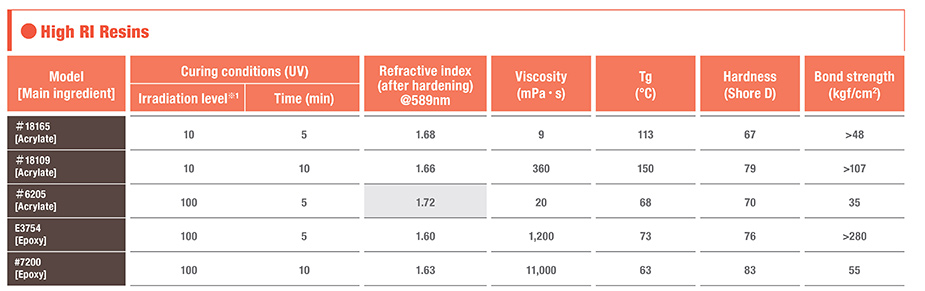

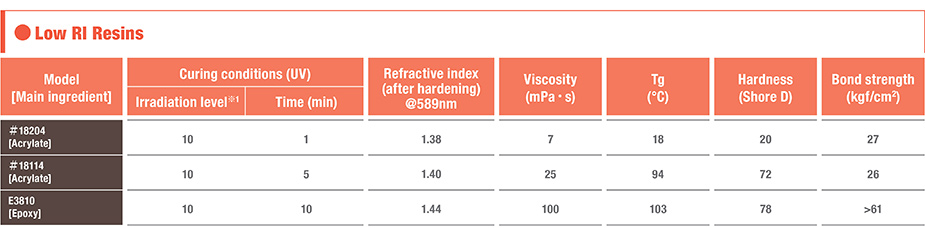

NTT Adhesives (UV-curable) & Sealants for Optical Devices

These adhesives & sealants have been developed by NTT Laboratories for application to optical devices.

Manufactured by |

Distributed by |

FAQs for NTT Adhesives Click Here to Order |

Download Spec Sheet (PDF)

Download Spec Sheet (PDF)

Download Spec Sheet (PDF)

Download Spec Sheet (PDF)

Download Spec Sheet (PDF)

Download Spec Sheet (PDF)

Download Spec Sheet (PDF)

Download Spec Sheet (PDF)